CVD Diamonds

31.10.17

For many centuries diamonds have been desired for its rarity, value, and brilliance, so it is not a surprise that someone would seek to replicate their beauty. Nowadays diamonds are synthesized in two ways: HPHT (high-pressure high-temperature) and CVD (chemical vapour deposition) synthesis. Today, we are going to focus on CVD synthesis and cover all significant aspects of it.

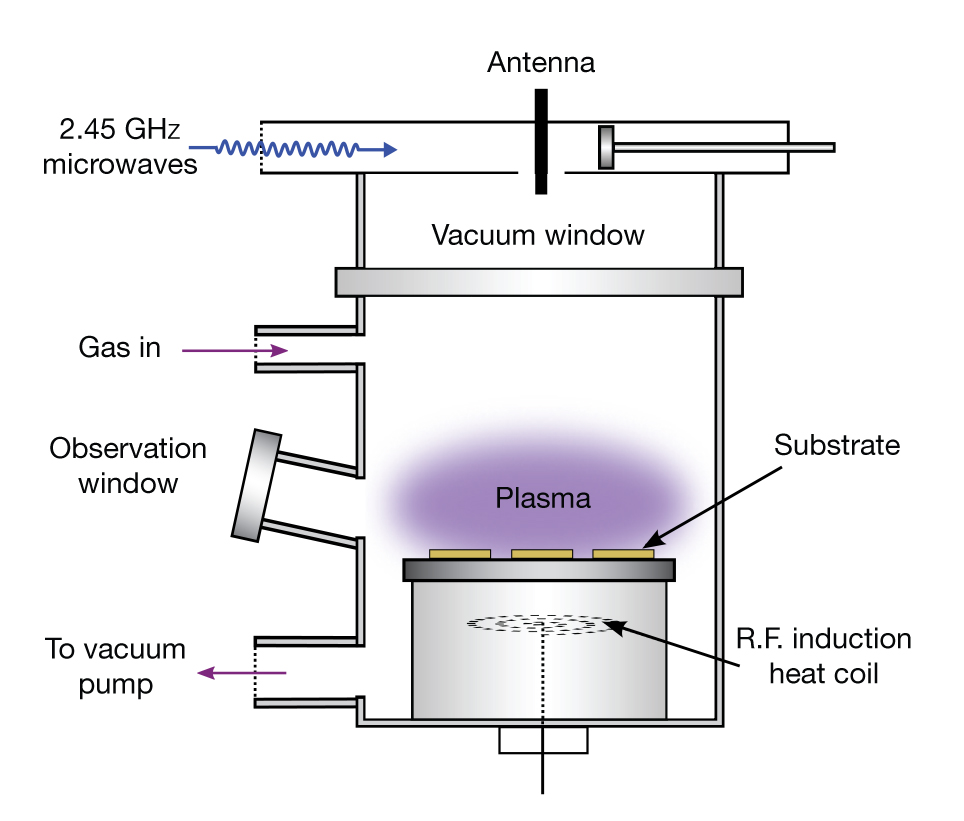

The first attempt to recreate the precious gemstone was in 1954 using the CVD method (two years before the announcement of HPHT synthesis); It was received with scepticism and was only reviewed years later. The CVD technique is entirely different from the natural formation process with the diamond is grown in moderate temperatures 700-1300 C, but very low pressure, less than 1 atmosphere. The formation starts in a vacuum chamber, a source of energy, like a microwave beam, heats up the mixture of a hydrocarbon gas, typically methane (CH4) and hydrogen (H2), breaking apart the gas molecules to release carbon atoms. These particles are drawn down toward the seed crystals at the bottom, which are typically flat, square-shaped seed plates, that are natural or, usually, synthetic diamonds. Crystallizations occurs relatively fast, with the growth rate up to 0.2 mm/hr. It takes up to several weeks to create numerous crystals at the same time. The exact number depends on the size of the chamber and the number of seed plates. The crystals appear tabular and square-shaped.

Figure 1. The diagram shows the main components of a microwave-plasma CVD reactor.

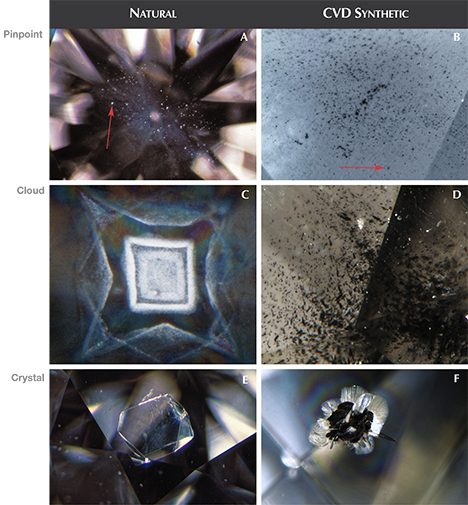

CVD process produces Type IIa diamonds that fall into the near-colourless range, although some have the brownish tint that can be easily removed by annealing. The research showed subsequent treatments like HPHT and irradiation could produce the fancy colouration in CVD diamonds, for example brown, pink, yellow and blue tones. Over the years the colour and the clarity characteristics were improved, demonstrating that more extended growth rate results in better quality stones. However, you can still come across specimens with a variety of inclusions like crystals, clouds, pinpoints, and feathers (this is very rare).

Figure 2. Inclusions in Natural diamonds compared to CVD synthetics.Photomicrographs by John I. Koivula (A and E), Sally Eaton-Magaña (B and D), Nathan Renfro (C), and Jonathan Muyal (F).

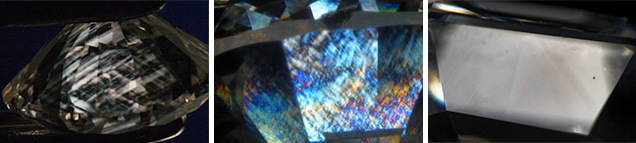

Although laboratories try their best to recreate visually identical replica, some gemological tests will determine its authenticity. When examined between two polarizing filters oriented at a 90-degree angle to each other, synthetic diamonds show various strain patterns that are diagnostic to CVD synthetic diamonds.

Figure 3. Viewed in crossed polarizers, CVD synthetics (left and center) show higher-order interference colours than those generally seen in type IIa natural diamonds (though this observation is not sufficient for a reliable identification). Viewing in crossed polarizers also distinguishes CVD from HPHT synthetics, which tend to display extremely low levels of strain (right). Shown in these photos are a 0.53 ct G-color CVD synthetic diamond (left), a 2.51 ct H-color CVD synthetic (center) and a 0.46 ct D-color HPHT synthetic (right). Photo taken by GIA laboratory.

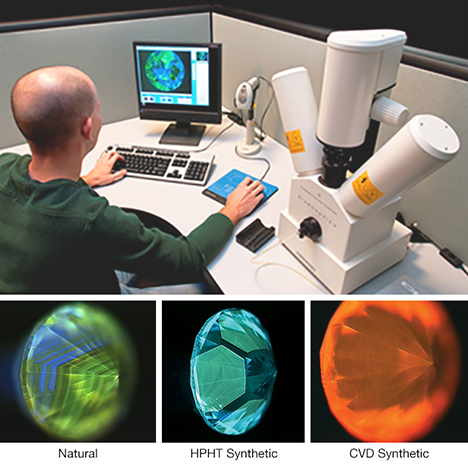

The stone can be tested with the Diamondview, which subjects the stone to the high intensity, high- energy UV source and gives its analysis in the form of images, where the fluorescent colours and patterns can be observed. As a result, CVD synthetic diamonds usually produce atypical colour fluorescence with uneven distribution. Common fluorescent colours seen are green, yellow-green, yellow, orange, or red. As mentioned earlier, CVD diamond growth takes place layer by layer on the top surface of the growing crystal, which is displayed in the form of thin curved luminescent striations when viewed with Diamondview, especially visible through the pavilion facets.

Figure 4. The DiamondView imaging system (top) enables to view growth patterns for natural and synthetic diamonds. The concentric growth pattern (left) identifies this stone as natural, while the cross-shaped pattern (centre) is diagnostic of an HPHT synthetic. The regular striations visible in the middle of this round diamond (right) indicate it is a CVD-grown synthetic. Photo by GIA laboratory.

In the jewellery industry CVD stones are not as common as HPHT synthetics. CVD’s are largely used in laser and electronic components, in optical windows, and as blades in cutting tools. These and other high-tech applications are the major driving force behind efforts to improve the growth process.

As artificially grown diamonds have become more common and harder to detect, IGR London continues to make synthetic diamond a top research priority.